Diesel Exhaust Aftertreatment

- Supplies

- / Diesel Exhaust Aftertreatment

Diesel Exhaust Aftertreatment

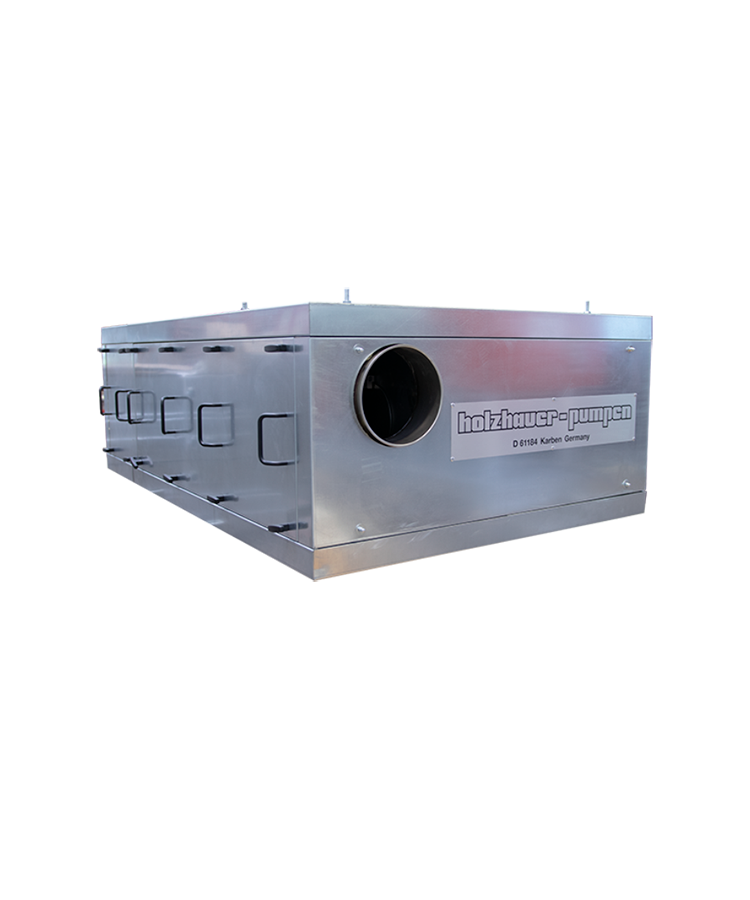

Modular passive exhaust gas aftertreatment system with continuous regeneration, for use with Holzhauer-Pumpen fire-fighting diesel engines according to VdS or NFPA/FM regulations.

With continuous regeneration.

As a complete unit ready for operation and installation for operation without additional auxiliary energy. The unit is equipped with one inlet and one outlet connection and can be integrated directly into the flue gas pipe system.

The filter inserts can be removed for maintenance without dismantling the housing. With complete thermal insulation and galvanised sheet steel cladding.

System performance

- Particle separation > 99.8 % (particle count measurement)

- CO reduction > 90%

- Soot number according to BOSCH < 0.5

- HCHO-formaldehyde up to 90%

- Reduction of exhaust gas temperature min. 350°C (filter inlet)

Expected emission data

- CO carbon monoxide < 30 mg/m³*

- Soot < 3 mg/m³*

*Values are based on exhaust gas volume flow at 5 vol.% residual oxygen

The system consists of sintered ceramic filter inserts with upstream oxidation catalysts in the required number and a safety bypass device to ensure the unrestricted operational readiness of the fire pump for the extinguishing duration even in the event of filter saturation resulting from possible motor malfunctions.

The passive particle filters are VERT approved by TRGS 554, BAFU, EMPA, Switzerland.

The unit is monitored electronically. All fault conditions are logged with all necessary data and can be read out. Faults are displayed on the pump control cabinet and are also available as a potential-free signalling contact for forwarding to a manned position.

The system is self-cleaning and does not require any maintenance by the system operator if it is operated properly and in accordance with its intended use and if the prescribed engine lubricants and fuels are used.

Fixing points for ceiling suspension on elevation are provided as standard.

Applications

Reference Projects

Power Plants and Recycling

Fire protection for Energieküste LNG terminal

Requirements The LNG terminal in northern Germany is a strategically important infrastructure project for Germany’s energy supply. As part of the “Energy Coast”, the…

Power Plants and Recycling

Fire protection for the dismantling of the nuclear power plant

Requirements Fire protection is a key issue when dismantling nuclear power plants. Our specially developed fire protection unit meets all safety-related requirements and is…

Retail

Stationary fire protection solution for Berlin shopping center

Requirements Shopping centers place complex demands on stationary fire protection systems. The aim of this project was to plan, manufacture, supply and install a…

Did you know …

We had already installed our company-owned QCTS Quality Control and Test System to ensure the highest product quality back in 1979.

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.