Electrical Fire Fighting Units

Compact, eco-friendly and quiet.

Space-saving with high performance, plug&play, no wiring required and minimum interfaces.

Our customers benefit greatly from the reduction to one single interface in order processing and significantly minimised effort due to:

- Established processes and partnerships that ensure solution-oriented engineering and on-time material procurement.

- Our technicians are highly competent, friendly and resilient when it comes to installing and maintaining our systems, including offshore.

- Due to our close cooperation with international insurers, we always find a safe solution during inspections.

- Our documentation is precise, easy to understad and functional.

We are a system supplier and a problem solver with VdS approval.

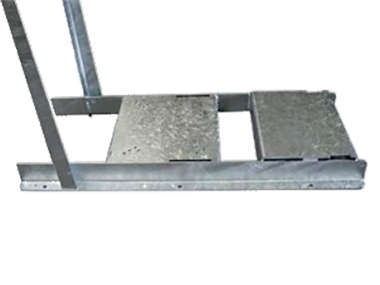

- Made of self-developed edge profiles

- Completely hot-dip galvanised in a full bath, according to DIN EN ISO 1461 with a protection duration class C3

- Due to steel sheets with increased material strength and corresponding construction, a considerably higher torsional stiffness is achieved than with comparable sectional steel base frames

- On request divided for better handling on the construction site

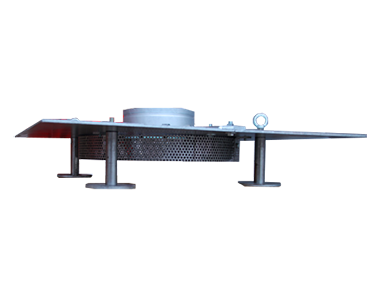

On request with SCHALLEX – structure-borne sound insulation

- External, easy and time-saving installation

- Installation with special fastening accessories without displacement of the pump set

- Integrated center holes as loading points for crane/transport

- For easy alignment of the pump set

- Front door labelling in the language of the order

- unit name plate showing technical data and approval numbers of the main components

- Elastic, vibration dampened mounting of the controller

- Pressure switch assembly completely installed and wired with wire break and short-circuit monitoring, piping with connection for flushing, discharge hose pipes for leaking water accumulated during tests of the unit, pressure gauge with dual scale showing measurements in bar and PSI and with adjustable pointer to mark the starting pressure

Further information on our VdS controller

- With or without flat suction basket, completely hot-dip galvanised

- Each unit will be tested using laser-optics and finely adjusted before delivery

- Metal spacers for fine adjustment in different thicknesses compensate alignment errors and allow re-adjustment after installation and during start-up

- An adjustment protocol is always included in the scope of delivery

Construction Types

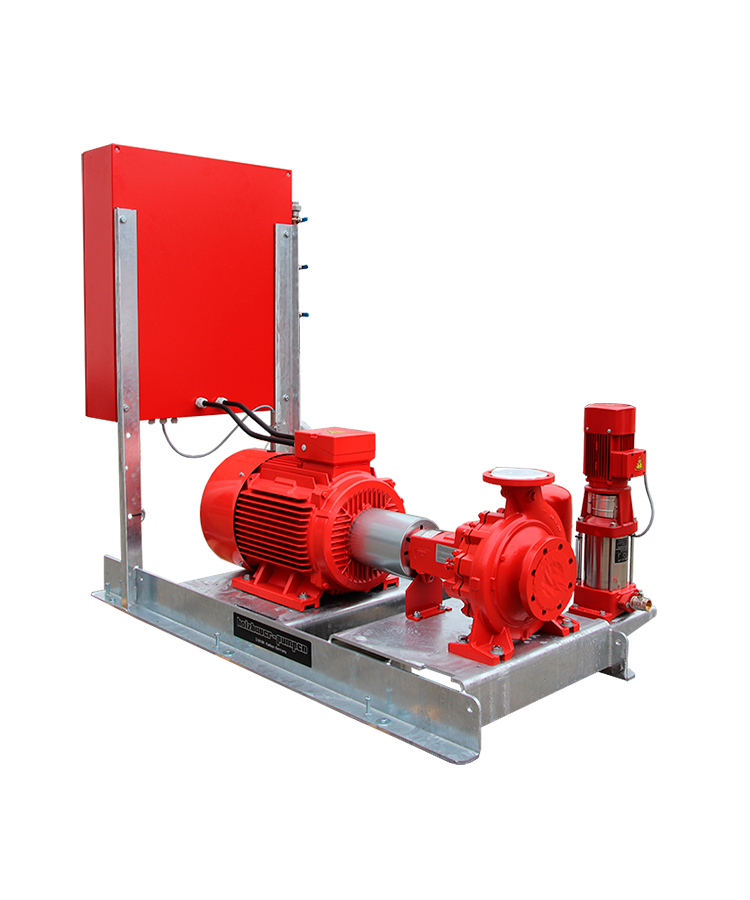

Common base frame with:

- Fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling and coupling guard

Delivered separately

- Controller for floor mounting or as an option with wall mounting flanges

Note: Special solutions without interconnecting wiring can only be recommended, if there are extremely difficult installation conditions on site, as they are uneconomic.

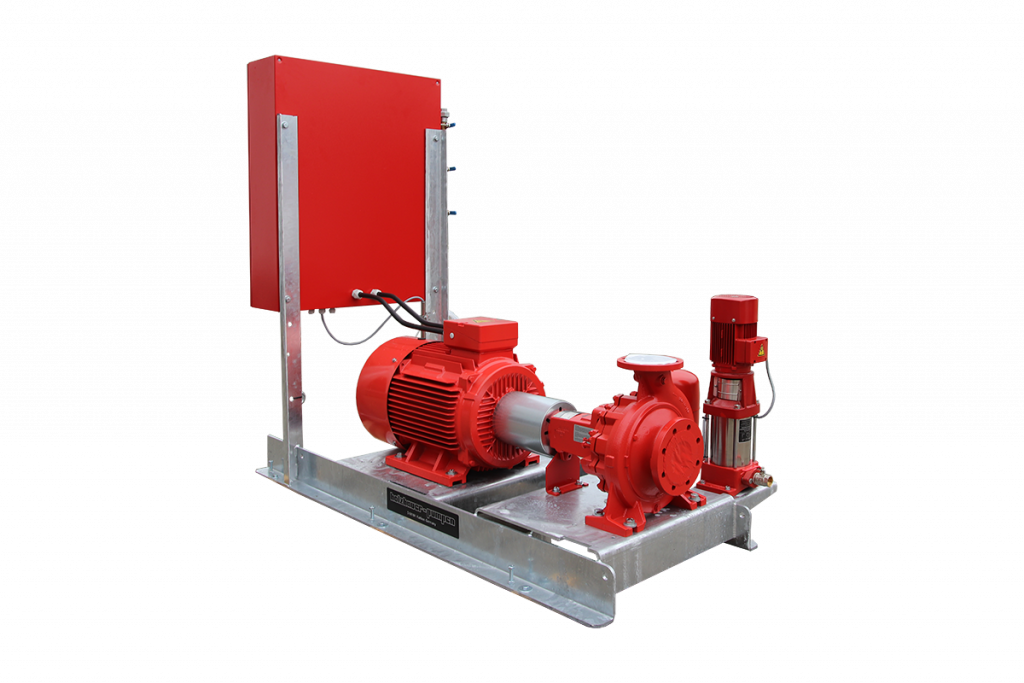

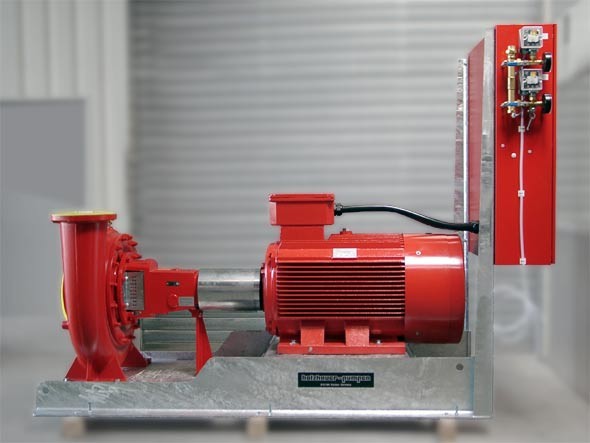

Common base frame with:

- Fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling with coupling guard

- Controller with pressure switch assembly consisting of 2 pressure switches with complete piping and interconnecting wiring to the electric motor

Common base frame with:

- Fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling with coupling guard

- Controller with pressure switch assembly consisting of 3 pressure switches with complete piping and interconnecting wiring to the electric motor

- Jockey pump unit, with all required fittings at the suction and discharge side, complete piping at the discharge side

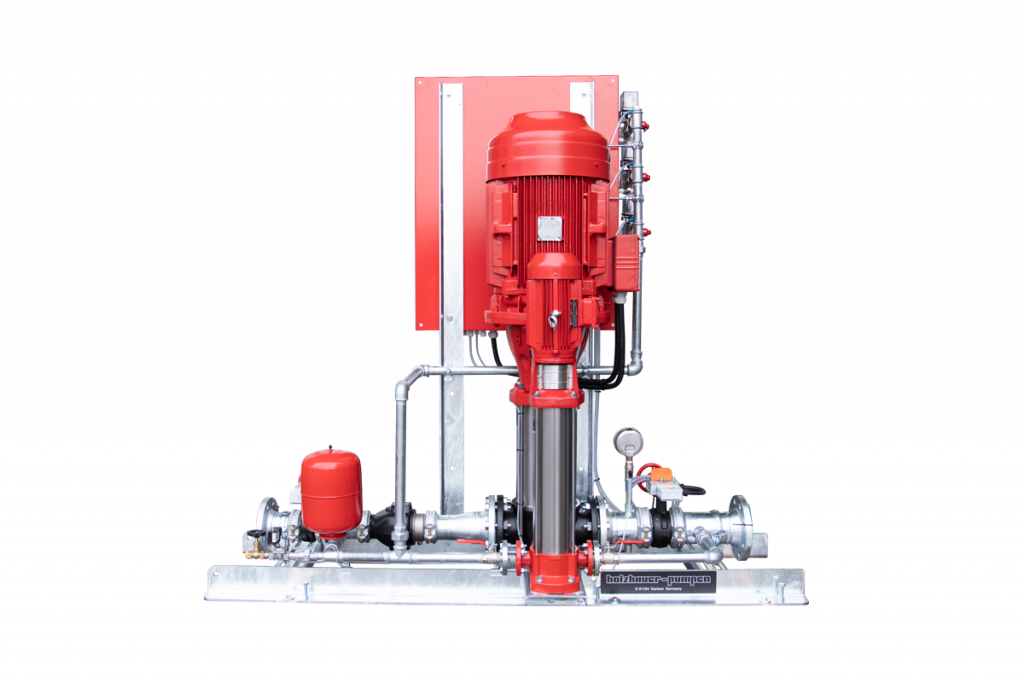

Common base frame with:

- Fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling with coupling guard

- Controller with pressure switch assembly consisting of 2 pressure switches with complete piping and interconnecting wiring to the electric motor

- Boiler feed pump, with all required fittings at the suction and discharge side, pressure gauges according to VdS-CEA

- Compressor, elastically mounted, for diaphragm pressure tank with all fittings, solenoid valve for pressure relief during starting process and screw connection R ¾”

Common base frame with:

- Fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling with coupling guard

- Controller with pressure switch assembly consisting of 2 pressure switches with complete piping and interconnecting wiring to the electric motor

- Boiler feed pump, with all required fittings at the suction and discharge side, pressure gauges according to VdS-CEA

- Compressor, elastically mounted, for diaphragm pressure tank with all fittings, solenoid valve for pressure relief during starting process and screw connection R ¾”

- Compressed air plant for up to 2 dry networks

- Automatic control

- Bypass with change-over from filling to automatic operation

- Lockable pressure relief valve

- Check valve

- Series tested safety valve

- Stop valve

- Turnable, flexible and oil resistant high pressure connecting hose with threaded joint

Common base frame with:

- fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling with coupling guard

- Controller with pressure switch assembly consisting of 2 pressure switches with complete piping and interconnecting wiring to the electric motor

- Boiler feed pump, with all required fittings at the suction and discharge side, pressure gauges according to VdS-CEA

- Compressor, elastically mounted, for diaphragm pressure tank with all fittings, solenoid valve for pressure relief during starting process and screw connection R ¾”

- 2 compressed air plants for 3 or more dry networks

- Automatic control

- Bypass with change-over from filling to automatic operation

- Lockable pressure relief valve

- Stop valve

- Series tested safety valve

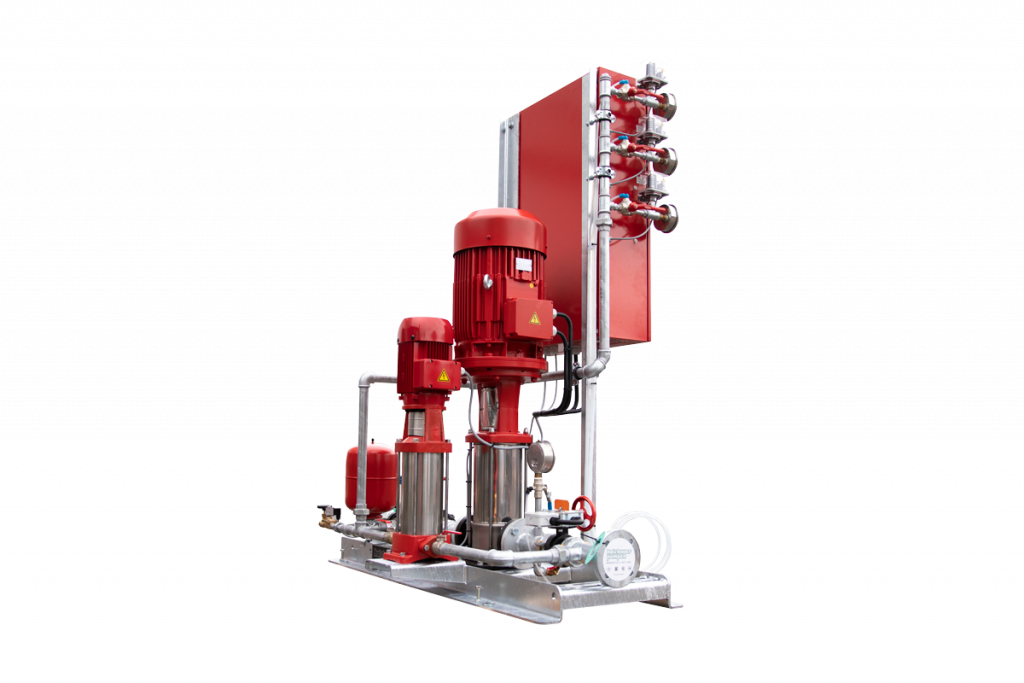

Common base frame with:

- Fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling with coupling guard

- Controller with pressure switch assembly consisting of 3 pressure switches with complete piping and interconnecting wiring to the electric motor

- Jockey pump unit, with all required fittings at the suction and discharge side, complete piping at the discharge side

- Compressed air plant for up to 2 dry networks

- Automatic control

- Bypass with change-over from filling to automatic operation

- Lockable pressure relief valve

- Check valve

- Series tested safety valve

- Stop valve

- Turnable, flexible and oil resistant high pressure connecting hose with threaded joint

Vertical pump package ready for connection and operation.

Common base frame with:

- Fire pump according to specification

- Electric motor, protection class IP 55

- Flexible coupling with coupling guard

- Controller with pressure switch assembly consisting of 2 pressure switches with complete piping and interconnecting wiring to the electric motor

Applications

Reference Projects

Power Plants and Recycling

Fire protection for Energieküste LNG terminal

Requirements The LNG terminal in northern Germany is a strategically important infrastructure project for Germany’s energy supply. As part of the “Energy Coast”, the…

Power Plants and Recycling

Fire protection for the dismantling of the nuclear power plant

Requirements Fire protection is a key issue when dismantling nuclear power plants. Our specially developed fire protection unit meets all safety-related requirements and is…

Retail

Stationary fire protection solution for Berlin shopping center

Requirements Shopping centers place complex demands on stationary fire protection systems. The aim of this project was to plan, manufacture, supply and install a…

Did you know …

We are a member of bvfa – Bundesverband Technischer Brandschutz e. V. and actively work on fire protection guidelines.

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.