Metal and Plastics Industry

- Applications

- / Metal and Plastics Industry

Metal and Plastics Industry

Due to their reliability, effectiveness and environmental compatibility, our fire protection systems are the ideal solution for the metal and plastics industry.

Requirements

Injection moulding, extrusion, casting, centrifugal casting, welding, abrasive cutting, soldering or flame cutting – production in the metal and plastics industry is particularly energy-intensive and flammable.

This makes the supply of cooling and extinguishing water an essential factor. The deployment of a reliable fire pump system that protects against the spread of fire in the event of an incident is standard in such areas. As an alternative to a sprinkler system, we also design, develop, manufacture, test and deliver water spray or foam extinguishing systems. Our systems detect and report fires, automatically initiate the extinguishing process and therefore provide reliable protection around the clock.

Solutions

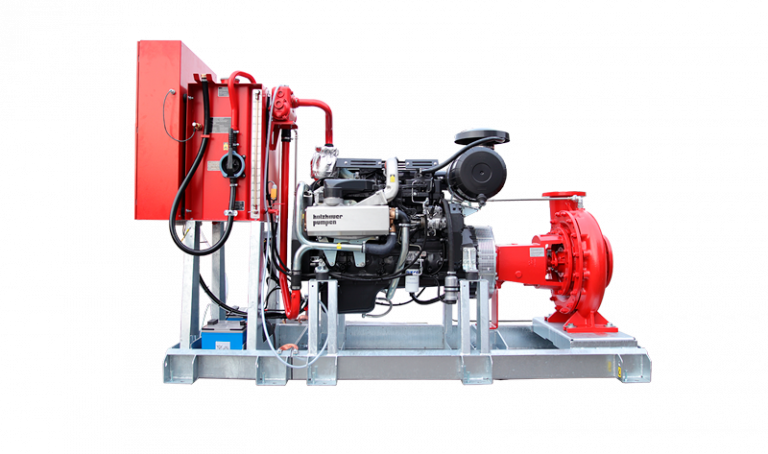

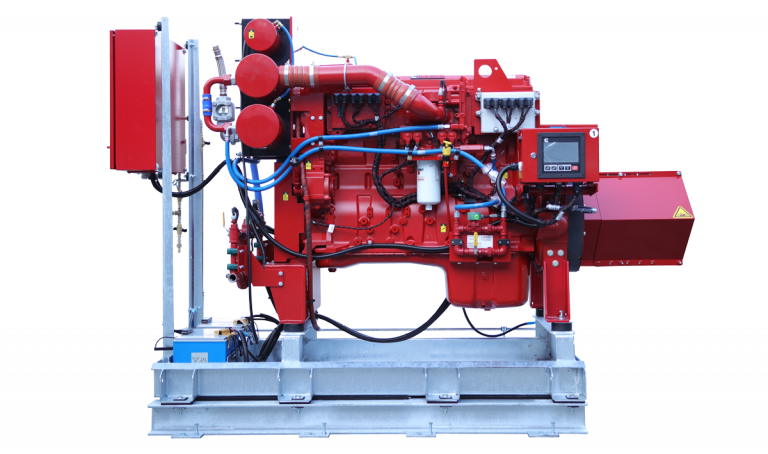

Holzhauer-Pumpen was significantly involved in developing the idea of supplying pump units in compact design more than 30 years ago. Since then, we have achieved the highest level of perfection when it comes to this design, which has enabled us to defend our technological leadership over the competition.

Further information about our VdS fire extinguishing units

Holzhauer-Pumpen was significantly involved in developing the idea of supplying pump units in compact design more than 30 years ago. Since then, we have achieved the highest level of perfection when it comes to this design, which has enabled us to defend our technological leadership over the competition.

Further information about our NFPA fire extinguishing units

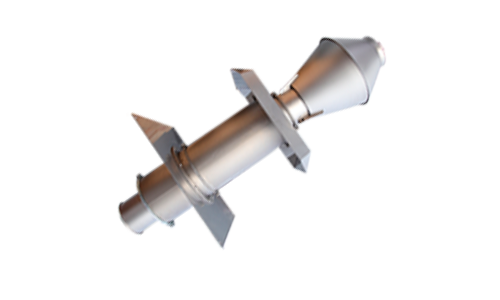

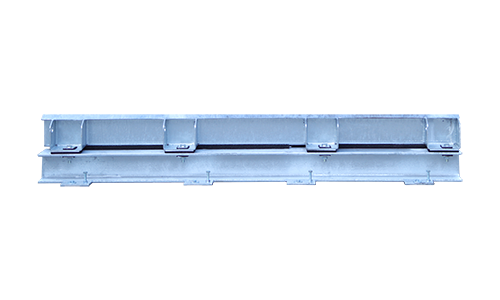

Our HSA exhaust system is equipped with all the necessary connection parts and components that are compatible with our units. This significantly reduces assembly times. The individual components also have a much lower weight than conventional, welded steel pipe systems, which in turn allows for assembly with minimal effort.

Further information on the HSA Exhaust System

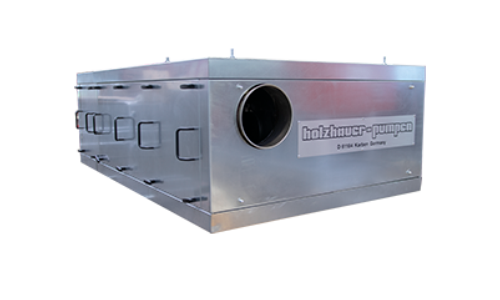

The exhaust gas aftertreatment for our diesel systems regenerates automatically, is equipped with a pressure and temperature probe and is connected to the controller.

Further information on exhaust gas aftertreatment

Noise has a negative effect on both the entire body as well as on our health. Diesel fire pump units are loud and subject to intense vibrations due to their design – thanks to our SCHALLEX system and other measures, such as encapsulation of the entire unit, we have managed to reduce vibrations and noise down to a minimum.

Further information on the SCHALLEX – Reduction of structure-borne noise

Our fully automatic pressure boosting systems reliably supply in the capacity range up to 1,500 m³/h and pressures up to 25 bar:

- Hydrant systems

- Service water systems

- Fire-fighting water circuits

- Water supply systems

The units are precisely matched, designed, manufactured and tested for the respective project specifications, pumped media and application requirements and, on request, approved on our performance test bench in accordance with all current national and international guidelines and standards. Optionally, a control room connection via PROFIBUS® / PROFINET® or Ethernet interface is possible.

Further information on booster pump units

Reference Projects

Power Plants and Recycling

Fire protection for Energieküste LNG terminal

Requirements The LNG terminal in northern Germany is a strategically important infrastructure project for Germany’s energy supply. As part of the “Energy Coast”, the…

Power Plants and Recycling

Fire protection for the dismantling of the nuclear power plant

Requirements Fire protection is a key issue when dismantling nuclear power plants. Our specially developed fire protection unit meets all safety-related requirements and is…

Retail

Stationary fire protection solution for Berlin shopping center

Requirements Shopping centers place complex demands on stationary fire protection systems. The aim of this project was to plan, manufacture, supply and install a…

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.