Prefabricated Pump Stations

- Engineered Products

- / Prefabricated Pump Stations

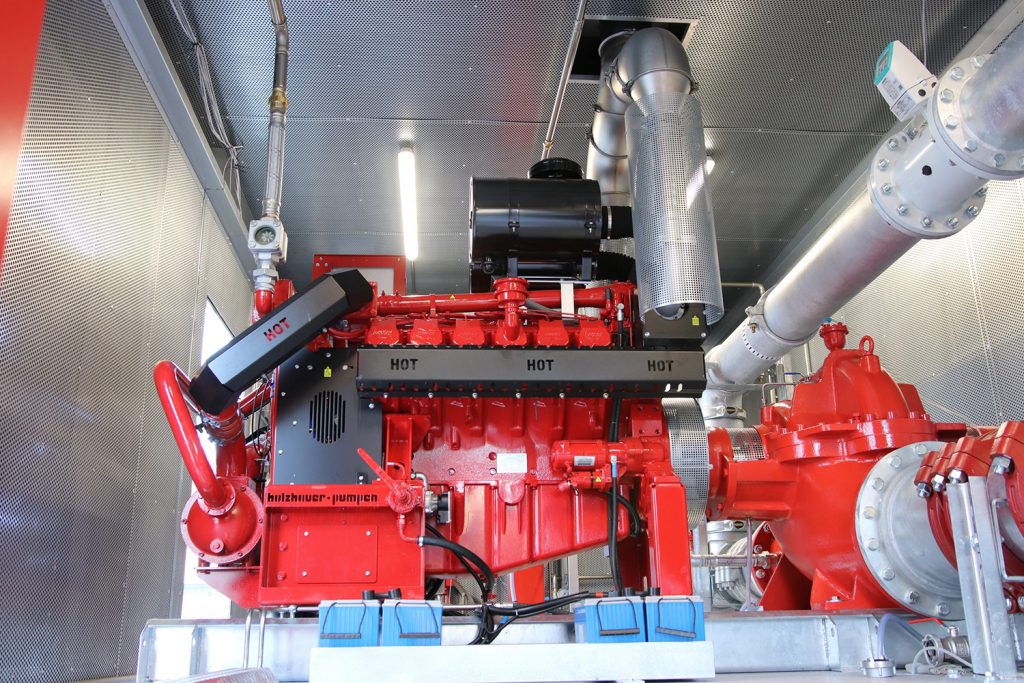

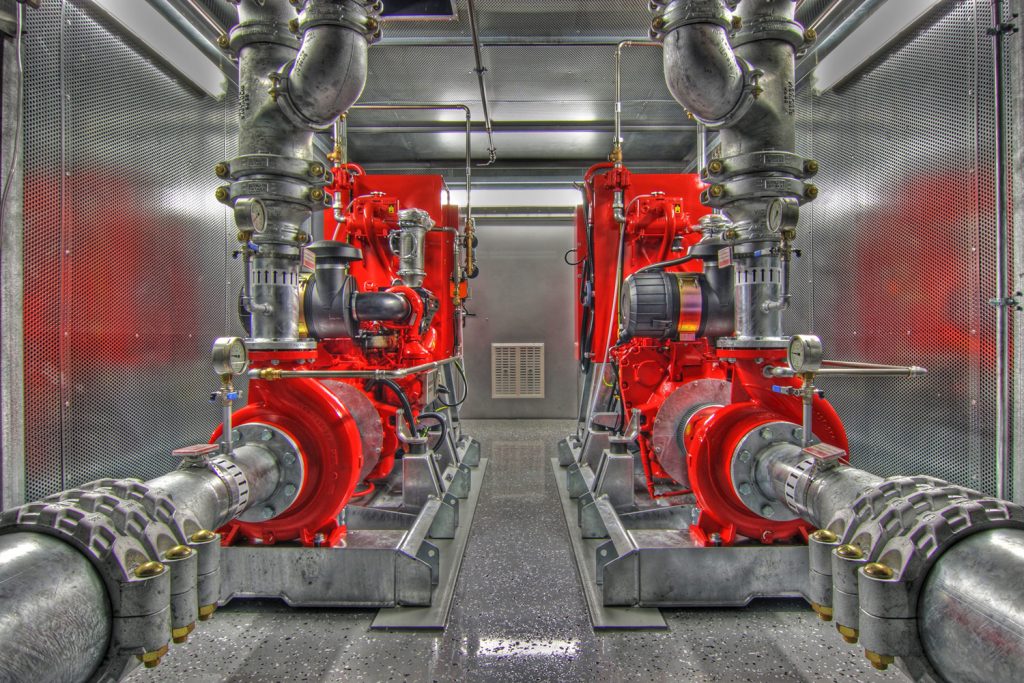

Prefabricated Pump Stations

Space-saving, with high performance, plug&play, no wiring required, reduced structure-borne noise and few interfaces.

Fire protection – compact.

The advantages of our compact prefabricated pump stations:

Space-saving, high performance, plug&play, no wiring required, reduced structure-borne noise and few interfaces. Our prefabricated pump stations, the material, design and installation comply with the following regulations and guidelines:

- DIN/UVV – Accident prevention regulations

- WHG – Water Resources Act

- TRbF – Technical guidelines for the storage of flammable liquids

- DIN-VDE – Standards

- GSG – German Equipment Safety Act

We are a system supplier with VdS approval and NFPA member.

Exemplary assembly

External dimensions possible as desired

Wall construction is performed project-specific. Galvanised steel profile sheet, 10 mm profile depth, fixed with rows of screws, steel framework, 50 mm mineral wool insulation in between, fire protection class A 1 (non-combustible) according to DIN EN 13 501, galvanised perforated sheeting on the inside, core insulation board with black fleece underneath.

- Environmentally friendly lead-free and low-solvent high-solid 2-component coating

- RAL colour of your choice (except special colours)

- Normal dry film thickness 50 – 60 μm

- Special crane lugs welded onto the roof frame, 4 pieces

- Reinforced version, designed for the above mentioned payload on the crane hook

- With tie rods for the above mentioned payloads extended version according to drawing

The roof is designed specifically for the project. Exemplary structure; roof structure from the outside to the inside:

Protective roof made of galvanised trapezoidal sheet metal, additionally plastic-coated similar to RAL 9002 grey-white, steel construction made of sectional steel – Plastic foil as barrier, 80 mm mineral wool insulation in between, fire protection class A 1 (non-combustible) according to DIN EN 13 501, snow load for single-storey installation 1.4 kN/m²

Steel fire door elements H 16 as required, fire-resistant ready-to-install element, tested and approved by the building authorities, door leaf 65 mm thick, rebated on 3 sides, sheet thickness 1.0 mm, bracing with flat steel.

With fire protection strips and 1 steel securing bolt, 2 construction hinges with ball bearings, special perimeter frame, 2.0 mm thick, with 3-sided EPDM seal, incl. TS 4000 overhead door closer, anti-panic lock for single-leaf door, emergency exit lock according to DIN EN 179, inside and outside with lever handle Door threshold profile for 1-leaf door with integrated anti-slip strip in signal colours (black/yellow stripes), with granulate bedding and storm chopper

- Structure from the inside to the outside

- Waterproof glued screen film panel d=18 mm

- Steel cross beams

- 60 mm mineral wool insulation

- Fire protection class A 1 (non-combustible) according to DIN EN 13 501

- Double layer on the crossbars to avoid cold bridges

- Galvanised sheet metal false floor

- Traffic load EG 3 kN/m²

- PU covering = polyurethane cast coating, seamlessly applied, laterally designed as a “tub” (except in the door area and in the area of possible breakthroughs), anti-slip by scattering of Trazino flakes, incl. clear varnish sealing, class of anti-slip R 10

- Fuse panel 400/230 V 50 Hz, with miniature circuit-breaker and N-disconnect terminals, incl. RCD 0.03A, 40A incl. RCD for lighting 0.03A, 25A incl. testing according to VDE 0100-700 incl. test plate, fire protection switch and overvoltage protection on site!

- Cover for SI panel, circuit diagram glued to inside of cover

- Test report for the above-mentioned electrical test, in paper form, single copy 01.19 1.00 piece Potential equalisation rail

- With external connection M 16 according to drawing

- Schuch LED-FR diffuser luminaire 28W 3840lm 16715L34G2 with energy efficiency class of the permanently installed light source A++(LED) protection class IP65, colour temperature 4000 K, 3840 lm and switch

- Schuko sockets as desired

- On request fixed connection / connection socket for heating, extra fuse protection

- On request with heating Stiebel Eltron wall convector type CNS 250 Trend, incl. wall bracket, 230 V, heat output 2.50 kW, weekly timer, frost protection and open-window detection, uniform, low-noise room air heating, setting range 5 – 30 ° C, on/off switch and overheating protection, adaptive control, calculation of preheating time in timer mode is automatic, protection class IP 24, splash-proof

- If desired, electric fan make Maico, type EN 31, delivery volume at 0 Pa 1500 m³/h, with automatic closing damper AS 30, electrical connection and control on site

Applications

Reference Projects

Power Plants and Recycling

Fire protection for Energieküste LNG terminal

Requirements The LNG terminal in northern Germany is a strategically important infrastructure project for Germany’s energy supply. As part of the “Energy Coast”, the…

Power Plants and Recycling

Fire protection for the dismantling of the nuclear power plant

Requirements Fire protection is a key issue when dismantling nuclear power plants. Our specially developed fire protection unit meets all safety-related requirements and is…

Retail

Stationary fire protection solution for Berlin shopping center

Requirements Shopping centers place complex demands on stationary fire protection systems. The aim of this project was to plan, manufacture, supply and install a…

Did you know …

We are a member of bvfa – Bundesverband Technischer Brandschutz e. V. and actively work on fire protection guidelines.

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.