Pump Connection Assemblies

- Supplies

- / Pump Connection Assemblies

Pump Connection Assemblies

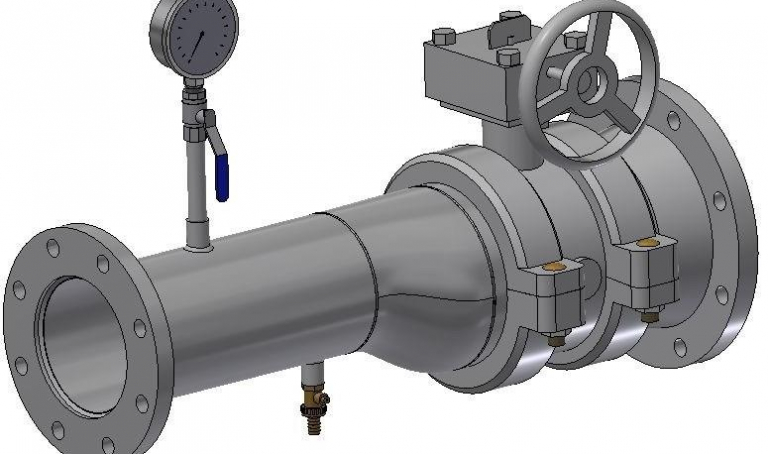

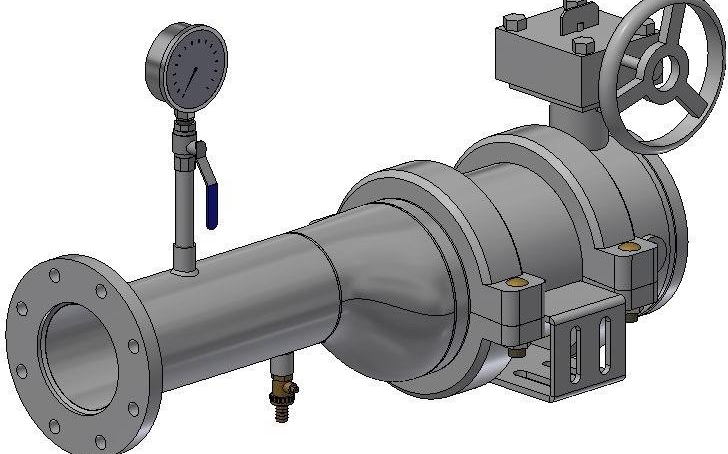

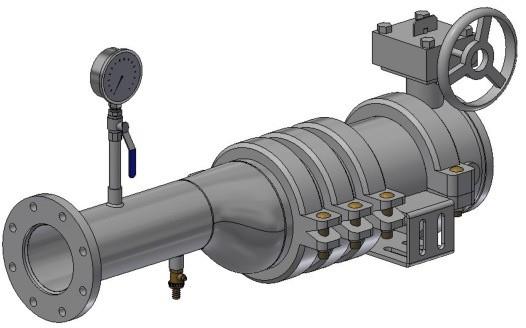

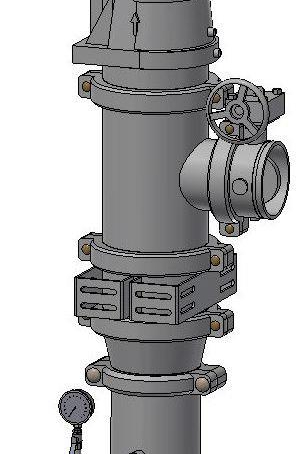

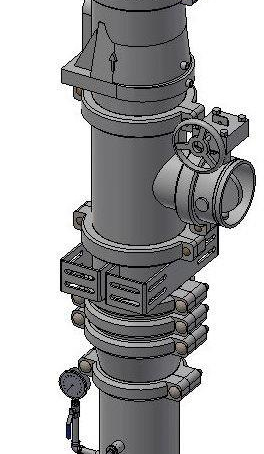

For pump suction and discharge side completely ready for installation and pressure-tested.

For pump suction side completely mounted.

Manufactured with reference to the VdS standard, components VdS approved

- Completely mounted and hydrostatically tested

- With all required screwed connections and gaskets for the suction flange of the pump

- On the inlet side with grooved connection (Victaulic oder Groovelok)

- Alternatively with flanged connection PN 10 or PN 16 (see figure), then including all required screwed connections, nuts and gaskets for the connection flange

With the following standard features:

- Pressure measuring according to the VdS standard, Pressure gauge, glycerine filled -1..+5 bar, stainless steel casing

stop valve with pressure relief hose - Eccentric pipe extension

- Butterfly valve with gear drive, hand wheel and monitoring switch

- Drain connection with ball valve and hose nozzle ½“

- Piping made of hot dip galvanized steel according to DIN EN ISO 1461

Available for all pump connection sizes and suction pipes from DN 65 up to DN 400

With the following standard features:

- Pressure measuring according to the VdS standard, Pressure gauge, glycerine filled -1..+5 bar, stainless steel casing

stop valve with pressure relief hose - Eccentric pipe extension

- Butterfly valve with gear drive, hand wheel and monitoring switch

- Drain connection with ball valve and hose nozzle ½“

- Piping made of hot dip galvanized steel according to DIN EN ISO 1461

- Available for all pump connection sizes and suction pipes from DN 65 up to DN 400

Similar to the STANDARD design but with additional:

- Multi-elongated hole connection points for fixed-point installation of the pipes, suitable for suspension or floor support

Similar to the STANDARD design but with additional:

- Vibration isolator (compensator) for the absorbtion of the machine vibrations

- Multi-elongated hole connection points for fixed-point installation of the pipes, suitable for suspension or floor support

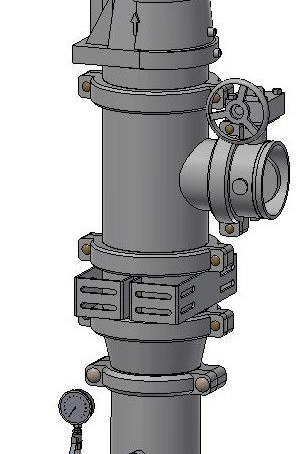

For pump discharged side completely mounted.

Manufactured with reference to the VdS standard, components VdS approved

- Completely mounted and hydrostatically tested

- With all required screwed connections and gaskets for the discharge flange of the pump

- On the outlet side with grooved connection (Victaulic oder Groovelok)

- Connection for test pipe

- Connection for circulation relief pipe

- Alternatively with flanged connection PN 10 or PN 16 (see figure), then including all required screwed connections, nuts and gaskets for the connection flange

With the following standard features:

- Pressure measuring according to the VdS standardPressure gauge, glycerine filled -1..+5 bar, stainless steel casing

stop valve with pressure relief hose - Concentric pipe extension

- Butterfly valve in the discharge pipe with gear drive, hand wheel and monitoring switch

- Butterfly valve for test pipe with gear drive, hand wheel and monitoring switch

- Check valve in the discharge pipe

- Drain connection with plug

- Connection point for circulation relief pipe

- Pipe parts made of hot dip galvanized steel according to DIN EN ISO 1461

Available for all pump connection sizes and discharge pipes from DN 65 up to DN 400, test pipes from DN 80 up to DN 200

With the following standard features:

- Pressure measuring according to the VdS standardPressure gauge, glycerine filled -1..+5 bar, stainless steel casing

stop valve with pressure relief hose - Concentric pipe extension

- Butterfly valve in the discharge pipe with gear drive, hand wheel and monitoring switch

- Butterfly valve for test pipe with gear drive, hand wheel and monitoring switch

- Check valve in the discharge pipe

- Drain connection with plug

- Connection point for circulation relief pipe

- Pipe parts made of hot dip galvanized steel according to DIN EN ISO 1461

- Available for all pump connection sizes and discharge pipes from DN 65 up to DN 400, test pipes from DN 80 up to DN 200

Similar to the STANDARD design but with additional:

- Multi-elongated hole connection points for fixed-point installation of the pipes, suitable for suspension or floor support

Similar to the STANDARD design but with additional:

- Vibrational compensator for the absorbtion of the machine vibrations

- Multi-elongated hole connection points for fixed-point installation of the pipes, suitable for suspension or floor support

Applications

Did you know …

Operators of commercially used buildings are usually required to take out a fire insurance policy.

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.