Supplies according to VdS

- VdS

- / Supplies according to VdS

Compact, eco-friendly and quiet.

We are happy to inform and advise you about our extensive range of accessories.

Clever down to the last detail.

Space-saving with high performance, plug&play, no wiring required, reduced structure-borne noise and few interfaces.

Our customers benefit greatly from the reduction to one single interface in order processing and significantly minimised effort due to:

- Established processes and partnerships that ensure solution-oriented engineering and on-time material procurement.

- Our technicians are highly competent, friendly and weatherproof when installing and maintaining our systems, including offshore.

- Due to our close cooperation with international insurers, we always find a safe solution during inspections.

- Our documentation is precise, easy to understand and functional.

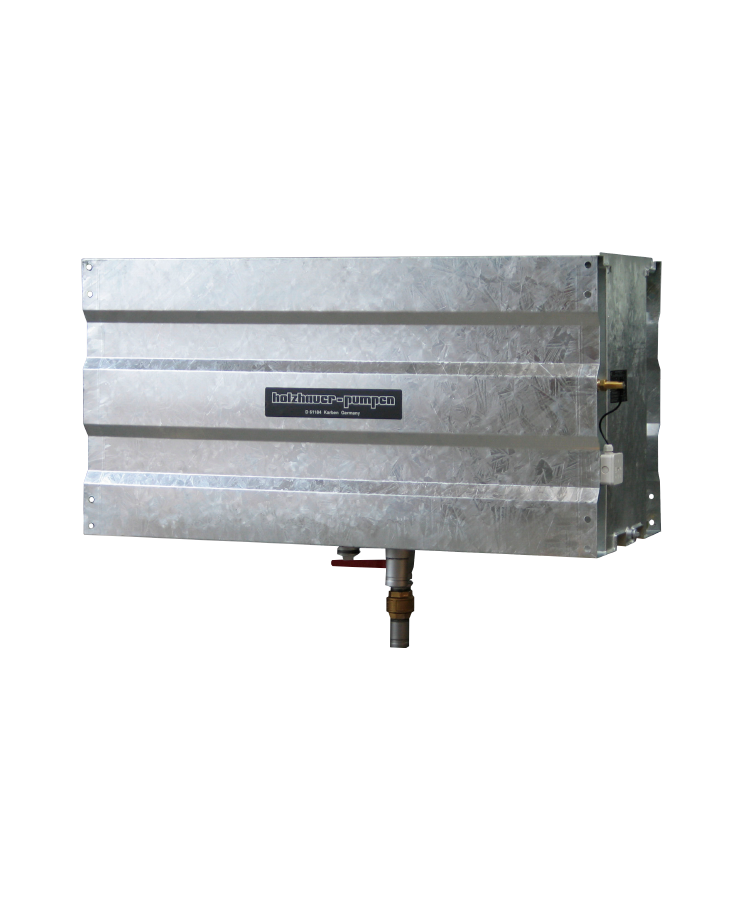

Pump fill up tank according to VdS-CEA, DVGW + DIN/EN 13077, 500l made of steel, hot dip galvanised with:

- 2 lever float valve DN 25 with float

- Shut off ball valve with tread R 1″ for suction side, according to DVGW

- Float switch for monitoring of the „MIN“– level short- fall checkable from the outside, with terminal box IP 54

- Water level volume indicator

- Overflow/drainage with pipe connector 2″ female

- Connection for pump filling pipe with check valve, gate valve and pipe connector 2″ female

- Connecting sleeve R 2“ in the bottom with plug as spare connection

- Connection points for floor rack

- Connection points for mounting with support

- Cover plate

Possible options:

- Wall mounting support for pump fill up tank 500 l as steel construction, hot-dip galvanised with complete mounting accessories

- Floor rack for pump fill up tank 500 l, suitable for installation heights 500 of 1.250 mm with base fixing plates, hot-dip

galvanised

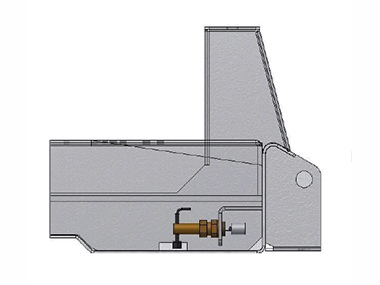

Ready-to-install and ready-to-connect tank frost protection units for extinguishing water storage tanks in monitored design. Fully automatic, energy-optimised frost protection heating controlled via electronic 5-point temperature controller, weather and water temperature. Including circulation pump and all necessary fittings. Fully function-tested with protocol prior to delivery.

Output 7.7 to 60 kW per unit.

Suitable for concrete and steel tanks of all sizes. Software-supported design adapted to the application on the basis of the tank data and the respective site data, min/max. air temperatures, wind speeds, etc.

Manufactured with reference to the VdS standard, components VdS approve.

- Completely mounted and hydrostatically tested

- With all required screwed connections and gaskets for the discharge flange of the pump on the outlet side with grooved connection (Victaulic oder Gruvlok)

- Connection for test pipe, connection for circulation relief pipe alternatively with flanged connection PN 10 or PN 16 (see figure)

- Including all required screwed connections, nuts and gaskets for the connection flange

With the following standard features:

- Pressure measuring according to the VdS standard pressure gauge, glycerine filled -1..+5 bar, stainless steel casing

- Stop valve with pressure relief hose Concentric pipe

extension - Butterfly valve in the discharge pipe with gear drive, hand wheel and monitoring switch Butterfly valve for test pipe with gear drive, hand wheel and monitoring switch

- Check valve in the discharge pipe Drain connection with plug

- Connection point for circulation relief pipe

- Pipe parts made of hot dip galvanized steel according to DIN EN ISO 1461

- Available for all pump connection sizes and discharge pipes from DN 65 up to DN 400

Manufactured with reference to the VdS standard, components VdS approved

- Completely mounted and hydrostatically tested

- With all required screwed connections and gaskets for the discharge flange of the pump

- on the outlet side with grooved connection (Victaulic oder Groovelok)

- Connection for test pipe

- Connection for circulation relief pipe

- Alternatively with flanged connection PN 10 or PN 16 (see figure), then including all required screwed connections, nuts and gaskets for the connection flange

With the following standard features:

- Pressure measuring according to the VdS standardPressure gauge, glycerine filled -1..+5 bar, stainless steel casing

- Stop valve with pressure relief hose

- Concentric pipe extension

- Butterfly valve in the discharge pipe with gear drive, hand wheel and monitoring switch

- Butterfly valve for test pipe with gear drive, hand wheel and monitoring switch

- Check valve in the discharge pipe

- Drain connection with plug

- Connection point for circulation relief pipe

- Pipe parts made of hot dip galvanized steel according to DIN EN ISO 1461

Available for all pump connection sizes and discharge pipes from DN 65 up

to DN 400, test pipes from DN 80 up to DN 200

Integrated into the drip pan of the base frame to indicate leakages of the diesel fuel tank and /or the diesel engine. With potential free contacts for external signal processing.

We manufacture

- Diesel fuel tanks with capacities from 180 to 5000 liters

- With 100% drip pan

- For floor or wall mounting

- Designed to meet all official regulations

- Suitable as storage or main storage tank

- Optionally with manual transfer pump devices to the diesel fuel service tanks on the pump units

- With leak detector and all other fittings

- The drip pans are always hot-dip glavanized as protection against corrosion but can also be painted (optional)

Double wall fuel tanks (750-2000 litres)

- Leak detection by a type tested, approved, completely assembled and calibrated vacuum leak detector

- Dimensions optimized and suitable for the installation conditions

- Floor racks in different heights matching the respective diesel engine

- Capacity between 1.000 and 3.000 litres

- Designed with internal plastic tank and external galvanised steel tank

- Suitable for automatic pressure refuelling by tankers

- Qualification approved, with manual transfer pump device

- Integrated 100%-drip pan in accordance with WHG with certificate and hose pipes

- All fittings necessary to fill/re-fill the diesel fuel service tank on the pump set

- With leak detector, level indicator, etc.

- High performance

- With double check valves

- Complete pipe connection to the diesel fuel tank at the discharge side

- With diesel fuel resistant suction tube at the suction side for extraction from a barrel, length dimensioned amply

- Support for suction tube

Differential pressure gauge with mounted and completely piped indicating device with the following features

- VdS approved

- Measuring range from 36 m³/h up to 1.087 m³/h

- Flow in every direction possible

- Measuring accuracy 2.5 % of the final value

- Indicating device rotatable by 180°

- Suitable for installation between 2 pipe flanges

- Nominal diameters from DN 80 up to DN 250

Additional accessories for test pipes such as fully automatic air release valves are available

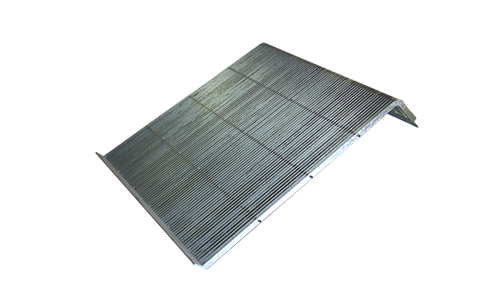

For systems with water withdrawal from surface water or rivers. Available in all required sizes and designs, also foldable and lockable for cleaning purposes.

Possible materials:

Hot-dip galvanised steel according to DIN EN ISO 1461

Stainless steel V2A

Stainless steel V4A

We calculate and design the intake screen as well as the complete intake structure for you!

Further information on inflow structures

Applications

Reference Projects

Power Plants and Recycling

Fire protection for Energieküste LNG terminal

Requirements The LNG terminal in northern Germany is a strategically important infrastructure project for Germany’s energy supply. As part of the “Energy Coast”, the…

Power Plants and Recycling

Fire protection for the dismantling of the nuclear power plant

Requirements Fire protection is a key issue when dismantling nuclear power plants. Our specially developed fire protection unit meets all safety-related requirements and is…

Retail

Stationary fire protection solution for Berlin shopping center

Requirements Shopping centers place complex demands on stationary fire protection systems. The aim of this project was to plan, manufacture, supply and install a…

Did you know …

We had already installed our company-owned QCTS Quality Control and Test System to ensure the highest product quality back in 1979.

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.