Compressed Air Supply

- Supplies

- / Compressed Air Supply

Compressed Air Supply

From compressors to fully automatic compressed air supply units for several or large systems.

Compact and safe.

Space-saving with high performance, plug&play, no wiring required, reduced structure-borne noise and few interfaces.

Our customers benefit greatly from the reduction to one single interface in order processing and significantly minimised effort due to:

- Established processes and partnerships thwt ensure solution-oriented engineering and on-time material procurement.

- Our technicians are highly competent, friendly and weatherproof when installing and maintaining our systems, including offshore.

- Due to our close cooperation with international insurers, we always find a safe solution during inspections.

- Our documentation is precise, easay to understand and functional.

We are a system supplier and a problem solver with VdS approval.

Types

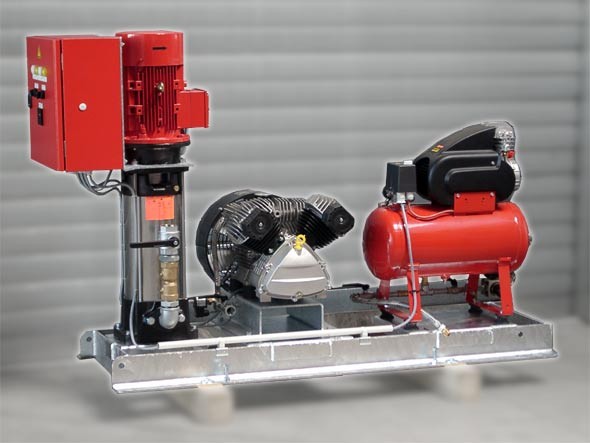

Compressor ready for operation and connection for pressurised water tank:

• Elastically mounted

• For compressed air water boilers with all fittings

• Start-up relief magnetic valve

• Compressed air connection R ¾” IG

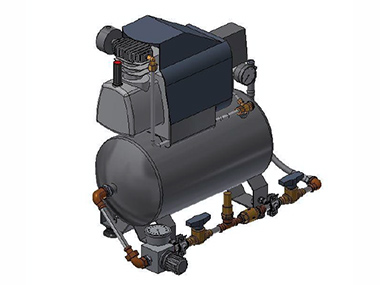

Compressed air supply system for up to 2 dry networks:

- Automatic control

- Bypass with switchover filling mode/automatic mode

- Pressure reducing valve lockable

- Non-return valve

- Type-tested safety valve

- Shut-off ball valve

- Rotatable, flexible and oil-resistant HD connection hose with screw fitting

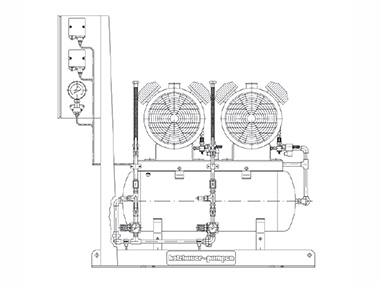

Fully automatic compressed air supply unit for multiple or large systems and large extensive dry line systems. Essentially with the following equipment:

- Shared steel base frame, completely hot-dip galvanised in a full bath according to DIN EN ISO 1461

- 2 piston compressors 1-stage 2-cylinder with compressed air aftercooler with three-phase drive motors 3-400 V, 50 Hz, IP 54

- Complete set of fittings piped and installed ready for operation

- Compressed air tank capacity 90 litres, PN 10

- Base-load pressure switch

- Peak load / reserve pressure switch

- Tank safety valve, component-tested

- Connection pipe groups for dry lines each with pressure reducing valve with blocking device (securing the setting against unauthorised adjustment), backflow preventer, safety valve, switching device for operating modes FILLING OPERATION/AUTOMATIC OPERATION with orifice for automatic operation, flexible connection hose for further pipelines, shut-off ball valve

- Control panel according to DIN VDE and UVV Operating voltage 3-400 V 50 Hz per compressor hand/off/automatic switch

- Motor protection switch with thermal and magnetic short-circuit release – Operating and fault lamp – Operating hours counter

- Automatic base load changeover between base load and reserve compressor at each new restart

- Automatic fault switchover, in the event of a fault in one compressor, the resting compressor starts automatically

Applications

Reference Projects

Power Plants and Recycling

Fire protection for Energieküste LNG terminal

Requirements The LNG terminal in northern Germany is a strategically important infrastructure project for Germany’s energy supply. As part of the “Energy Coast”, the…

Power Plants and Recycling

Fire protection for the dismantling of the nuclear power plant

Requirements Fire protection is a key issue when dismantling nuclear power plants. Our specially developed fire protection unit meets all safety-related requirements and is…

Retail

Stationary fire protection solution for Berlin shopping center

Requirements Shopping centers place complex demands on stationary fire protection systems. The aim of this project was to plan, manufacture, supply and install a…

Did you know …

Holzhauer-Pumpen was founded back in 1969 and has since developed into a leading and globally recognised supplier of pump installations worldwide.

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.