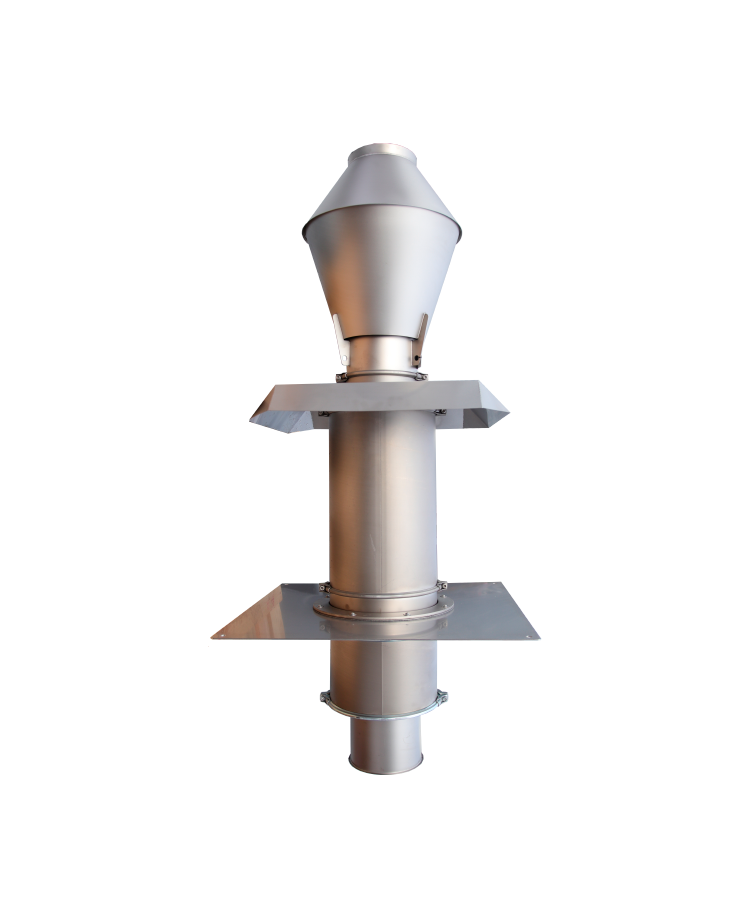

HESA Exhaust System

- Supplies

- / HESA Exhaust System

HESA Exhaust System

For more than a decade, our stainless steel exhaust system HESA has been available for all diesel propulsion engines (fire pumps, generators).

For all diesel engines.

Nominal sizes 80, 120, 150, 200 and 250 mm are available from stock, a special version with thermal insulation is planned.

The exhaust system is a simple, pressure-tight exhaust system that can be assembled without welding, with all the necessary connection parts and components matched to our units, which allows considerable savings in assembly time. The individual components have a much lower weight than conventional welded steel pipe systems. This means that assembly can be carried out with minimum effort.

Product advantages

Significant savings in assembly time and effort due to couplings that are simple, safe and quick to assemble and relatively low weights compared to conventional systems welded from steel tubes.

High and durable corrosion resistance.

Fitting and special lengths are manufactured to the millimetre on request.

We guarantee the dispatch of the complete system within two working days after receipt of the order from our warehouse in Karben. This makes it possible to assemble and order the required material on the construction site after final installation of the pump unit and taking into account the construction site conditions without any loss of time.

A comprehensive range of components for almost any task, including the necessary silencers and complete exhaust gas aftertreatment systems with oxidation catalytic converters and particle filters for compliance with current and expected future emission requirements is available.

We provide a comprehensive support concept with fixed point and floating bearings.

Suitable expansion pipes as well as high-performance hose compensators to the motor connection are available to absorb expansion movements as well as vibrations.

HSA exhaust silencers must always be attached to the pipe sockets provided with fixed point clamps.

The components are made of chrome-nickel steel 1.4301 (X5CrNi18-10) or AISI304 (V2A) 1.4307 (X2CrNi18-9) with a wall thickness of 1 mm. The tubes are laser welded.

The use of the original pipe couplings in conjunction with the highly temperature-resistant graphite sealing elements with 2 stainless steel inserts also results in mechanically resilient, secure, longitudinally force-locking and pressure-tight pipe connections that can be equated with welded flange connections. The general requirements for exhaust systems are fully met.

The HSA system can be used up to operating pressures of 500 mbar and operating temperatures of up to 600°C.

The system is pressure surge resistant up to 2000 mbar.

A quality control checks all flange surfaces for flatness and parallelism.

Applications

Reference Projects

Power Plants and Recycling

Fire protection for Energieküste LNG terminal

Requirements The LNG terminal in northern Germany is a strategically important infrastructure project for Germany’s energy supply. As part of the “Energy Coast”, the…

Power Plants and Recycling

Fire protection for the dismantling of the nuclear power plant

Requirements Fire protection is a key issue when dismantling nuclear power plants. Our specially developed fire protection unit meets all safety-related requirements and is…

Retail

Stationary fire protection solution for Berlin shopping center

Requirements Shopping centers place complex demands on stationary fire protection systems. The aim of this project was to plan, manufacture, supply and install a…

Did you know …

A functioning sprinkler system is often a requirement when applying for a building permit.

Let us help you!

Our employees explain and illustrate the requirements of standards and regulations as early as the initial consultation phase and thus facilitate the implementation and safe application in your daily work. In addition, they present engineering expertise spanning 50 years of hands-on application and research and thus provide our customers with a decisive competitive edge.